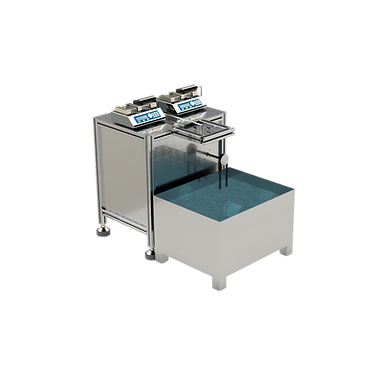

Automatic hollow fiber membrane casting machine

The Automatic Hollow Fiber Membrane Casting Machine is a state-of-the-art system engineered for the continuous and precise fabrication of hollow fiber membranes. Designed with advanced automation, it minimizes manual intervention, enhances reproducibility, and ensures consistent membrane quality. This machine is ideal for R&D centers, pilot plants, and industrial-scale membrane development in water treatment, pharmaceuticals, and gas separation industries.

Key Features

Fully Automated Operation – PLC/touchscreen interface for streamlined control of spinning, coagulation, and take-up processes.

High Precision Control – Automated regulation of polymer dope flow, bore fluid flow, and spinning parameters.

Integrated Coagulation & Washing Baths – Ensures uniform fiber formation and improved membrane performance.

Heating & Temperature Regulation – Maintains stable process conditions for dope solution and coagulation media.

Continuous Fiber Collection – Automated take-up and winding for uninterrupted production.

Safety & Reliability – Built with protective features and durable, corrosion-resistant materials.

Applications

Manufacturing hollow fiber membranes for ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO)

Water and wastewater treatment membrane development

Biotechnology and pharmaceutical separation processes

Gas separation and specialty membrane R&D

Pilot-scale and industrial-scale production facilities